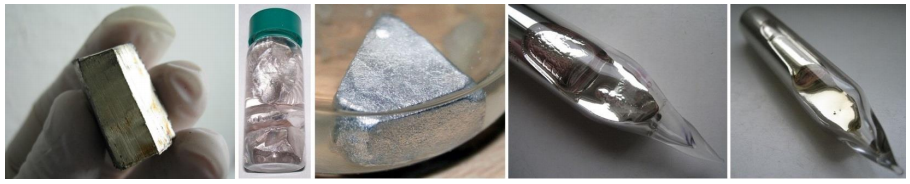

In their pure forms, the alkali metals (lithium, sodium, potassium, rubidium, and cesium) are soft, shiny metals with low melting points. Alkali metals react readily with air and moisture. Due to their reactivity, special precautions must be taken when using and storing these metals.

Lithium, sodium, potassium, rubidium, and cesium (L-R).

What are the hazards?

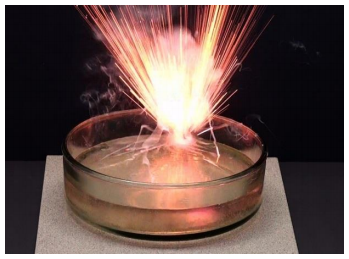

Alkali metals react with air to form caustic metal oxides. The heavier alkali metals (rubidium and cesium) will spontaneously ignite upon exposure to air at room temperature.

Alkali metals react with water to produce heat, hydrogen gas, and the corresponding metal hydroxide. The heat produced by this reaction may ignite the hydrogen or the metal itself, resulting in a fire or an explosion. The heavier alkali metals will react more violently with water.

How can I protect myself?

BEFORE WORKING WITH ALKALI METALS

- Develop a Standard Operating Procedure (SOP) for your experiment and review the SOP with your Principal Investigator (PI).

- Read more about SOP development.

- Ensure personnel working with alkali metals have completed appropriate Tier III (laboratory-specific) training, which includes a review of the SOP.

- Ensure that an appropriate Class D fire extinguisher is available prior to beginning work with alkali metals. Contact the Stanford University Fire Marshal’s Office at (650) 723-0448 to obtain these extinguishers. ABC and CO2 fire extinguishers must not be used to extinguish alkali metal fires.

WORKING WITH ALKALI METALS

- When possible, work with alkali metals in a glove box, as a glove box can provide an inert working environment.

- If it is necessary to work with these metals outside of a glove box, perform this work in a certified laboratory fume hood. The work area must be free of water, extraneous flammable materials, and sparks or other ignition sources.

o To prevent reaction with air, keep alkali metals under an inert solvent such as mineral oil, hexanes, or toluene.

o Use air-sensitive techniques when handling alkali metals outside of a glove box. Resources for airsensitive techniques include Sigma Aldrich Technical Bulletin AL-134 and ChemistryViews Tips and Tricks for the Lab: Air-Sensitive Techniques.

Minimum PPE for alkali metal work includes:

- Safety glasses o Gloves of the appropriate chemical resistance

- Flame-resistant lab coat

- Proper street clothing – long pants (or equivalent clothing that covers the legs and ankles) and closetoed, non-perforated shoes that completely cover the feet.

- Do not work alone when handling alkali metals

How do I store this?

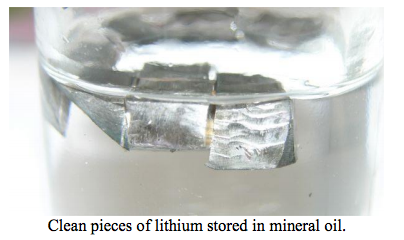

To minimize contact with oxygen and water, alkali metals must be stored in an airtight container under mineral oil and/or under an inert gas, such as argon. Glove boxes with an inert atmosphere are an appropriate location for the storage of alkali metals.

Specific storage notes for lithium:

- Nitrogen gas is not an inert atmosphere for lithium, as lithium will react with nitrogen to form a dark coating of lithium nitride.

Pieces of lithium with visible lithium nitride tarnish.

- Lithium (density: 0.534 g/cm3 ) will float in mineral oil (density: 0.8 g/cm3 ). Ensure pieces of lithium stored in oil are thoroughly coated.

- Alternatively, lithium may be stored under a layer of petroleum jelly or paraffin wax.

Specific storage notes for potassium:

- Potassium must always be stored under an inert atmosphere. Even when kept under mineral oil, a yellow coating of potassium superoxide may formafter prolonged storage if oxygen is present in the headspace of the container.

- Potassium superoxide can form an impact-sensitive explosive with mineral oil.

- Alkali metals are classified as Storage Group B in the Stanford Storage Group Classification System. This group is not compatible with any other storage group and must be stored separately.

How do I dispose of this?

- Scraps of alkali metal waste may be stored in the same fashion as bulk metal (i.e., under mineral oil and/or an inert atmosphere). EH&S will pick up alkali metal scraps stored in this manner as hazardous waste.

- Create hazardous waste tags and request pickup of hazardous waste on the WasteTag system.

- Do not quench alkali metals unless it is a necessary part of the experimental procedure.

- If quenching is necessary, provide a detailed description of the quenching procedure in the SOP. Consult with EH&S at (650) 723-0448.

- Care must be taken when cleaning equipment and tools used to work with alkali metals. Possible methods include rinsing with isopropanol or tertbutanol (which react more slowly with alkali metals) or immersion in a large amount of ice water. Consult with your PI to determine the appropriate course of action.

- Solid materials (such as gloves, paper towels, or kimwipes) contaminated with small amounts of alkali metal may be collected inside metal cans, to protect against the fire risk posed by a delayed reaction of residual alkali metal with air. These cans are available from Stanford EH&S.

Reference

- Urben, P.G. Bretherick’s Handbook of Reactive Chemical Hazards, 7th ed.; Academic Press: Burlington, MA, 2007.

- Ho, T.-L.; Fieser, M,; and Fieser, L. Fieser and Fieser’s Reagents for Organic Synthesis. John Wiley & Sons, Inc.: Hoboken, 2006.

- ESPI Metals. “Potassium (K).”