To minimize injury or death from incidents involving slips, trips, and falls, Stanford has developed prevention procedures, including worksite evaluations, hazard elimination, and employee training.

The objectives of these procedures are to:

- Identify working environments where slip, trip, and fall hazards are most likely to occur.

- Eliminate identified hazards.

- Train Stanford employees working in environments where hazards are likely to arise.

The responsibilities listed below supplement the core responsibilities outlined in the Injury and Illness Prevention subtopic.

Supervisors

Supervisors are responsible for the following:

- Identifying work locations that are “Higher Risk Areas.” For definition of “Higher Risk Area,” refer to the next section, “Hazard Identification.”

- Ensuring periodic workplace inspection is conducted to identify slip/ trip/ fall hazards.

- Properly addressing slip, trip and fall hazards promptly and consulting with EH&S if a slip, trip and/or fall hazard cannot be abated.

- Ensuring appropriate training is provided for all employees who will be working in higher risk areas where slip, trip and fall hazards are prevalent.

- Evaluating employees’ compliance with safe work practices.

- Where routine or occasional floor cleaning is performed by departmental staff, creating a floor maintenance procedure and ensuring that personnel properly and consistently follow floor maintenance procedures.

- Promptly reporting all employee injuries to Stanford’s Risk Management Department by completing and submitting the appropriate forms (e.g. SU 17, DWC Form 1, 5020 Form). For clarification of reporting requirements or unusual circumstances, call Risk Management at (650) 723-4554.

Employees

Employees who work in a higher risk area are responsible for the following:

- Adhering to the recommended housekeeping practices & other safe work practices to prevent slip, trip and fall related incidents. This includes cleaning up spills immediately, marking spills and wet areas, mopping or sweeping debris from floors, and removing obstacles from walkways, and keeping areas free from clutter.

- Following all safety practices as listed in the University’s Injury and Illness Prevention Program, including but not limited to:

- Reporting potential hazards to the supervisor immediately.

- Reporting accidents to the supervisor immediately.

Building Managers and Zone Managers

Building managers and Zone managers are responsible for the following:

- Assisting in the identification and elimination of slip, trip and fall hazards found in common/shared areas. Inspections for identifying slip, trip and fall hazards are recommended:

- At least annually, ideally prior to a wet season.

- Before, during, and/or after construction and renovation activities in situations where building occupants and the general public may be affected.

- Review the sample Slip Trip Fall Inspection Form for more guidance.

- As appropriate, assisting departments with the removal of facilities-related slip, trip and fall hazards.

- Consulting with EH&S for assistance in addressing slip, trip and fall hazards as appropriate.

Department of Environmental Health and Safety (EH&S)

The EH&S Occupational Health and Safety Department is responsible for the following:

- Developing, implementing, and maintaining the Slip, Trip and Fall Prevention Guide.

- Assisting departments in evaluating areas where slip, trip and fall hazards are prevalent and providing suggestions to help abate noted deficiencies.

- Making available training for employees who work in areas where slip, trip and fall hazards are prevalent.

- Analyzing and reporting trends in injury and/or incidence rates related to slip, trip and fall hazards, using data reported by Zurich, Risk management, and government sources.

Slip, trip, and fall hazards

Common slip, trip, and fall hazards result from:

- Wet or contaminated floors (e.g. grease, liquids, ice, oil, dust, fine powders, etc.)

Contaminant

Source

Rain water

- Transmitted internally from open external doors or from the feet, coats, or umbrellas of pedestrians

- Building leaks

Water, other fluids

From spills, plumbing leaks, cleaning, ice machines

Floor cleaning products

Resulting from failure to follow appropriate cleaning protocol

Body fluids

Blood, vomit

Condensation

Variations in temperature

Dusts

Natural or from stored materials

Debris

Bags, paper, food residues, soil, or cardboard boxes

Other possible sources:

- Uneven walking surfaces, holes, changes in level, broken or loose floor tiles, defective or wrinkled carpet, or uneven steps or thresholds

- Mats or rugs not laying flat on the floor

- Obstructions and accumulation of objects in walkways (e.g. hoses, cords, cables, debris, etc.)

- Unguarded platforms, walkways, and work areas 30 inches above ground

- Inadequate illumination (see the Design Guidelines for specific requirements)

Higher-risk areas

Any area where a slip, trip, or fall hazard is likely to arise during a typical work shift is considered a higher-risk area. Examples include:

- Dining hall kitchens (wet floors)

- Locker rooms (wet floors)

- Loading docks (elevated locations)

Inspections

Inspections to identify slip, trip, and fall hazards are recommended at least annually, and ideally prior to the wet season. For higher-risk areas, a formal inspection is recommended at least on a quarterly basis, or more frequently, depending on the likelihood for changing conditions. For common areas, the building manager should conduct inspections. (See the Slip Trip Fall Inspection Form.)

Recommended inspections should minimally include the following:

- Condition of floors, carpets, and steps

- Floor maintenance protocol

- Housekeeping practices

- Lighting levels

- Presence and condition of guardrails or handrails at elevated work surfaces (see the Design Guidelines for specific requirements)

General Housekeeping Procedures and Safe Work Practices

The following housekeeping procedures and safe work practices must be followed to prevent accidents associated with slip, trip and fall hazards:

General Safety

- Avoid running or walking too fast, especially in higher risk areas.

- Avoid carrying items that will obstruct one’s view of their walking pathway.

- Avoid walking through potential slip, trip and fall hazards.

- Use extra caution when traveling both outdoors and indoors during/ following wet weather.

General Housekeeping Procedures

- Clean up spills immediately. For greasy liquids, use suitable cleaning agent.

- Do not leave floors wet after cleaning – clean them to a completely dry finish if possible. If “clean-to-dry” is not possible, then use barriers and “wet floor” warning signs to keep people off the wet area.

- Use cleaning methods that do not spread the problem. Small spills are often better dealt with using a paper towel instead of a mop that wets a larger area of floor.

- Do not use cardboard to soak up spills.

Slip Hazards

- Floors, platforms, and walkways shall be maintained in good repair, and reasonably free of oil, grease, or water. Mats, grates, or other methods that provide equivalent protection shall be used on areas where operation requires walking on slippery surfaces.

- Slip-resistant floor coatings should be used in areas that are likely to get wet or subject to frequent spills.

- Slip hazards must be identified and removed promptly.

- Warning signs or other equally effective means (barricades) should be used as a warning system in areas where a slip hazard is present.

Trip Hazards

- Platforms and walkways shall be free of obstructions & dangerous projections (e.g. extension cords, power cables, hoses, carts, boxes, debris).

- Position equipment to avoid cables crossing pedestrian routes; use cable covers securely fix to surfaces, or consider use of cordless tools.

- Surfaces in poor repair (i.e. holes, surface upheaval, and broken tiles) shall be repaired or guarded by readily visible barricades, rails or other equally effective means.

- Ensure floor mats and rugs are securely fixed and do not have curling edges.

Fall Hazards

- Elevated Locations

- Guardrails shall be provided on all open sides of unenclosed elevated locations. Examples of elevated locations include: balconies, runway ramps, or working surfaces that are more than 30 inches above the floor, ground, or other working areas of a building.

- For Roofs: Guardrails shall be provided at locations where there is a routine need for an employee to approach within 6 feet of the edge of the roof. Where such roof access is needed no more than 4 times a year, safety belts, lanyards, or an approved fall protection system may be used in lieu of guardrails.

Stairways

- Stairways shall have handrails or stair rails on each side. Refer to the Design Guidelines tab for specific requirements.

Ladder Use

- When a ladder is used, the employee shall follow safe ladder practices. Ladder safety training is available from EH&S for Stanford University employees. Department-specific training may be arranged upon request (contact EH&S 723-3635 for more information).

- If using Elevating Work Platforms & Aerial Devices (e.g. vertical tower, scissor lift, mast-climbing work platform): Only employees who have been trained and approved by the supervisor shall operate elevating work platforms and aerial devices. NOTE: Aerial device and elevating work platforms are vehicle-mounted or self-propelled device sdesigned to elevate a platform/individual in a substantially vertical axis.

Floor Mats and Other Floor Treatments

Where work processes are expected to create wet floor surfaces, such surfaces shall be protected against slipping by using mats, grates, cleats, or other methods that provide equivalent protection. Where wet processes take place, drainage shall be maintained and false floors, platforms, mats, or other dry standing places provided.

Floor mats

Floor mats shall be placed in building entrances and higher risk areas where walking-working surfaces may encounter wetness or other slippery conditions. Examples of these areas include:

- Areas adjacent to food counters and food preparation areas

- Cooking areas

- Dishwashing areas

- Frying stations

The design of floor mats should have the following features:

- Slip-resistant surface on both top and bottom sides.

- Beveled edges, flat edges or similar design to help reduce the likelihood of workers tripping on the mat’s edges.

- Slots or similar design to help promote drainage and prevent accumulation of water & grease.

- Antibacterial treatment or similar design to help prevent the growth of mold and mildew.

Floor mats should not be installed and used in such a way that the mat itself becomes a slip or trip hazard. Where wet processes are used, drainage shall be maintained and false floors, platforms, mats, or other dry standing places provided.

Slip-Resistant Footwear

Employees who work in potentially slippery higher risk areas must wear slip-resistant footwear. When selecting slip-resistant footwear, the following should be considered:

- Level of slip-resistance (i.e. Polyurethane and microcellular urethane soles are more slip-resistant compared to nitrite and styrene rubber).

- Tread design, tread hardness, and shape of sole and heel (i.e. High elastic soles with raised-tread and cross-hatch patterns are more slip-resistant than rough and flat soles. Tread patterns should cover the whole sole and heel area.)

- Proper support and comfort.

NOTE: The use of slip-resistant footwear alone is not adequate to prevent slip-related accidents. General housekeeping procedures, safe work practices, and matting/floor treatments (as necessary) must be used.

Floor Maintenance Procedures

A floor maintenance procedure must exist where routine or occasional floor cleaning is performed by departmental staff. It is recommended to consult with the floor cleaner product’s manufacturer for guidance on suggested cleaning procedures. The following should be considered when developing a floor maintenance procedure:

- The type of floor finish products used, including slip-resistant polymer finishes, strippers, degreasers and general cleaners.

- Proper application methods for products, including proper dilution and time schedules for each component or process.

- Proper warning system used during floor maintenance operation to alert building occupants of the presence of potential slip, trip and fall hazards.

- Documentation of products used, including Material Safety Data Sheets, and specifications regarding the slip-resistance level of the product.

- Periodic review of maintenance program, especially after a report of an employee “near miss” or actual accident.

For employees working in higher-risk areas, training shall be provided to ensure that employees comply with safe work practices. Department-specific trainings may be arranged upon request.

General housekeeping/safe work practices

All employees who may work in a higher-risk area shall be trained on:

- Recognizing potential hazards

- The use of control measures to prevent slip, trip, and fall-related accidents

The supervisor, building manager, and EH&S will determine the frequency of training.

Floor maintenance procedures

- Where departmental staff are assigned to perform routine or occasional floor maintenance, training should be provided.

- When new products and/or equipment are used, departmental staff should receive adequate re-training.

Recordkeeping

Supervisors shall keep records of health and safety training received by employees for at least one year, except for training records of employees who have worked for less than one year, which are provided to the employee upon termination of employment (in accordance with Stanford’s Illness and Injury Prevention Program and 8 CCR 3203).

Guardrails

Per Cal/OSHA, guardrails shall be designed to comply with the following standards:

- Guardrails shall be provided on all open sides of unenclosed elevated work areas, such as roof openings, platforms, ramps, or any other working location more than 30 inches above the floor, ground, or other working areas of a building. The only exceptions are platforms, ramps, runways, or other working levels constructed prior to January 1, 1967 that are less than four feet above the floor, ground, or other working level.

- A standard guardrail shall consist of a top rail, a midrail, or equivalent protection and posts.

- The distance between the floor and the upper surface of the top rail shall be within the range of 42 to 45 inches.

- The top rail shall be smooth-surfaced through the length of the railing.

- The midrail shall be approximately halfway between the top rail and the floor, ground, or other attached surface. Note that local building regulations may require a nine inch spacing of midrails.

- Guardrails shall be mounted such that the top rail is capable of withstanding a downward load of 20 pounds per linear foot, applied either horizontally or vertically.

Handrails

Per Cal/OSHA, handrails shall be designed to comply with the following standards:

- Stairways shall have handrails or stair rails on each side. Every stairway required to be more than 88 inches in width shall be provided with at least one intermediate stair rail for every 88 inches of required width. Exceptions include:

- Stairways less than 44 inches in width may have one handrail, unless the other side of the stairway is open. In that case, the open side shall have a handrail.

- Stairways with less than four risers are not required to have a handrail.

- Stairways giving access to portable work stands less than 30 inches high are not required to have a handrail.

- The upper surface of handrails shall be placed no less than 34 inches or no more than 38 inches above the nosing of treads and landings.

- Handrails shall be continuous for the full length of the stairs.

- Handrails shall be designed to prevent falls by providing a grasping surface to the user.

- For handrails projecting from a wall, the space between the wall and the handrail shall be at least one and a half inches.

- The mounting of handrails shall be such that the completed structure is capable of withstanding a load of at least 200 pounds, applied in any direction, at any point on the rail.

Stairways

Per Cal/OSHA 8 CCR 3231, the designs of stairways shall comply with the following standards:

- Stairways that serve an occupant load of more than 50 shall have a width of no less than 44 inches.

- The run shall not be less than 10 inches, as measured horizontally between the vertical planes of the furthermost projection of adjacent treads. The largest tread run within any flight of stairs shall not exceed the smallest by more than 3/8 inch. The greatest riser height within any flight of stairs shall not exceed the smallest by more than 3/8 inch.

- Treads of stairways shall be slip-resistant.

- Headroom clearance of stairways shall be no less than six feet, six inches. Such clearance is determined by measuring the vertical distance between a plane parallel and tangent to the stairway tread nosing to the soffit above at all points.

Ramps

Per Cal/OSHA 8 CCR 3232, the designs of ramps shall comply with the following standards:

- Surfaces of ramps shall be roughened, or shall be made of non-slip materials.

- Ramps that serve any exit way, provide handicap access, or are in the path of travel shall not have a slope that exceeds one foot rise to twelve feet of horizontal run. As an exception, existing ramps shall not exceed one foot rise to eight feet of horizontal run.

- Ramps with slopes exceeding one foot rise to 15 feet of horizontal run shall have handrails or stair rails, as required for stairways.

- Ramps more than 30 inches above the adjacent ground or floor are to be provided with guardrails.

Loading docks

For loading docks equipped with a dock lift:

- Posts, stanchions, and chain rails, or other guardrails which will provide equivalent protection when the dock lift is not in active use shall be installed to prevent accidental falls from the dock level down to the lowered dock lift.

- Posts, stanchions, and chain rails, or other guardrails which will provide equivalent protection, should be located at least three feet from the edges of the dock lift.

- Dock levelers and dock plates shall be rated to support the expected load.

- Awareness training on recognizing the potential hazards of working in an elevated area must be provided to employees working at loading docks.

Lighting

Working areas, stairways, aisles, passageways, work benches, and machines shall be provided with either natural or artificial light, which must be adequate and suitable to provide a reasonably safe place of employment.

Minimum levels of illumination for safety

Hazards requiring visual detection slight high Normal activity level Low High Low High Areas Offices, locker rooms, storage yards Loading areas, warehouses, corridors, washrooms Elevators, stairways, assembly area Engine rooms, processing area, machine shop Foot-candles 0.5 1.0 2.0 5.0

Mobile phone use while walking (including texting, emailing, and talking) is increasingly common. According to a recent survey, as many as 60% of pedestrians use mobile phones while crossing the street (Liberty Mutual Insurance, 2013). These behaviors are linked to an increased risk of pedestrian incidents and injuries. In the U.S., accidents involving phone-distracted pedestrians are estimated to have increased three-fold from 2004 to 2010 (Nasar & Troyer, 2013).

Mobile phone use while walking (including texting, emailing, and talking) is increasingly common. According to a recent survey, as many as 60% of pedestrians use mobile phones while crossing the street (Liberty Mutual Insurance, 2013). These behaviors are linked to an increased risk of pedestrian incidents and injuries. In the U.S., accidents involving phone-distracted pedestrians are estimated to have increased three-fold from 2004 to 2010 (Nasar & Troyer, 2013).Stanford University is not immune to such risks. Over the past few years, serious pedestrian incidents have occurred at campus intersections, stairways, and walkways. Considering the prevalence of mobile phone use at Stanford, along with increasing campus traffic and construction activities, pedestrians and bicyclists are urged to take the following simple safety measures:

- Be continuously aware of your surroundings.

- If you need to use your phone, stop walking or biking.

- Avoid using headphones while walking and biking, especially in high-traffic areas.

- Before crossing the street, look both ways for oncoming car or bicycle traffic. Make eye contact with motorists and cyclists before crossing.

- Use handrails when walking up or down stairs.

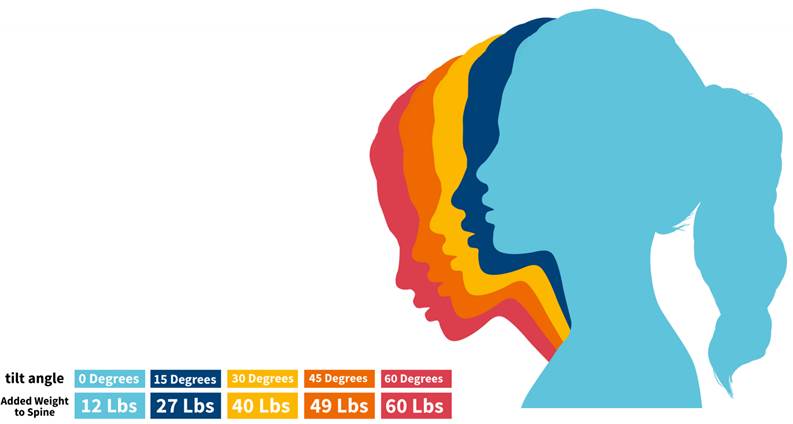

Looking down at your phone can also have negative health affects. The more you angle your neck, the more pressure you put on your spine:

For questions, contact EH&S at (650) 723-0448.