Background

Early microbiologists had to rely on open flames to ensure sterility while engaging in certain techniques. With the advancement of modern technology, including the introduction of the Biosafety cabinet, the use of an open flame is almost always no longer necessary. In fact, the use of open flames in a Biosafety cabinet

- disrupts the air flow, compromising protection of both the worker and the work

- causes excessive heat buildup, may damage HEPA filters and/or melt the adhesive holding the filter together, thus compromising the cabinet’s integrity

- presents a potential fire or explosion hazard. Electrical components such as the fan motor, lights and electrical outlets are not designed to operate in flammable atmospheres, where a flash fire could be ignited by a spark (Figure 5).

- inactivates manufacturers warranties on the cabinet: cabinet manufacturers will assume no liability in the event of fire, explosion or worker exposure due to the use of a flammable gas in the cabinet. Additionally, the UL approval will automatically be void.

For information regarding Universal Precaution signs, see Chapter 4.

Recommendations

Stanford University has taken a strong stance against the use of gas burners or alcohol flames in Biosafety cabinets. The decision has been made in accordance with recommendations from numerous agencies. The Centers for Disease Control and Prevention (CDC) reports that “open-flames are not required in the near microbe-free environment of a biological safety cabinet” and create “turbulence which disrupts the pattern of air supplied to the work surface,” jeopardizing the sterility of the work area. This is also the recommendation of the World Health Organization (WHO) as well as the major Biosafety cabinet manufacturers.

The use of such devices is not only extremely dangerous, but can also inactivate manufacturer’s warranties. There are many alternatives to the use of burners: microincinerators, disposable tissue culture supplies, etc.

Solutions

- Follow good BSC work practices (Figure 6)

- Remove Bunsen burners and/or replace with alternative technology such as electric incinerators

- Use disposable loops, spreaders, and other instruments

- Autoclave instruments such as tweezers, scissors and scalpels

- Reduce the amount of flammable chemicals in the cabinet. Use only enough alcohol for one day’s work

- Use alcohol to sterilize any glass, etc. that is being used. Allow to evaporate before opening or dry with a Kimwipe

- If it is deemed absolutely necessary for the work being done, use a pilotless burner or touch-plate microburner to provide a flame on demand

Important Information

Important Information

BSC Usage: Best Practices

- Turn on BSC and let run for 5 – 10 minutes before using

- Wipe down cabinet surfaces with appropriate disinfectant

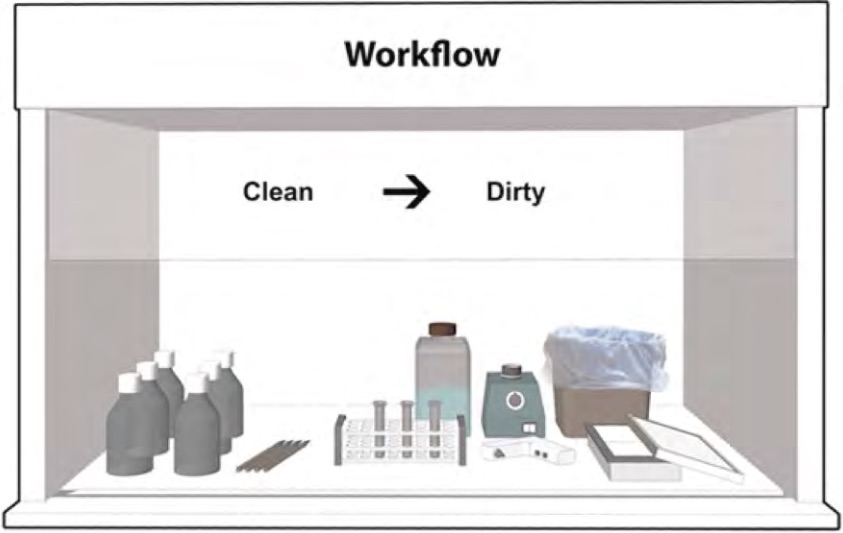

- Arrange work surface from “Clean” to Dirty”, keeping air grilles clear of materials

- Disinfect and remove all materials from cabinet after use

- Leave BSC running for 5–10 minutes after use

- Wipe down cabinet surfaces with appropriate disinfectant